Biggie K and Ice Cube

At PURPL, we seek to create solutions for propulsion and to gather as much information as possible from testing. Right now, in the Test Infrastructure team, our first and main test stand is called Biggie-K. I work on the DAQ, the data acquisition system, called Ice Cube.

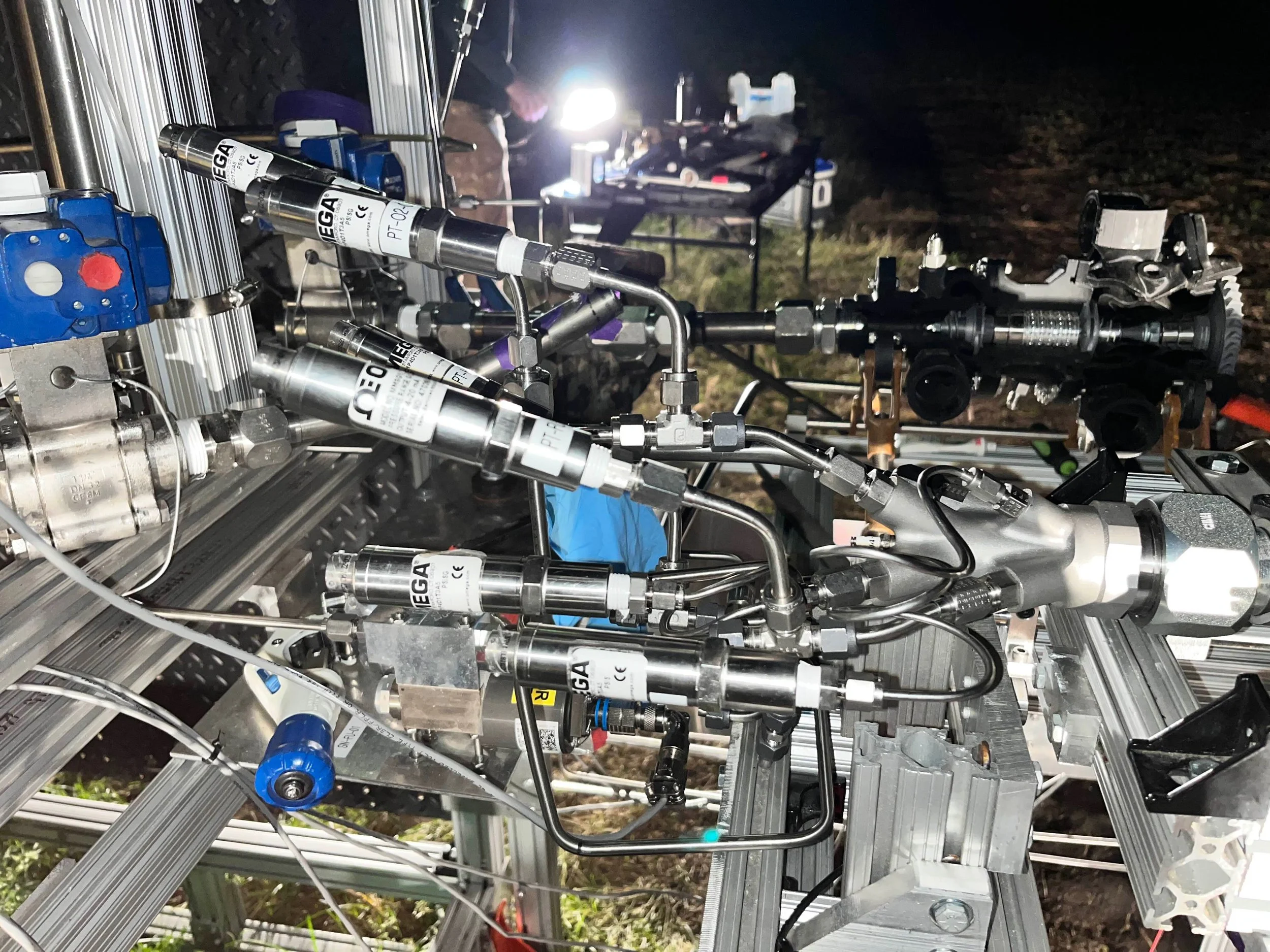

Picture from spring 2025 test campaign, here you can see the fluid panel, thrust structure, and test article

A close up of pressure transducers on the torch igniter that was fired in spring 2025

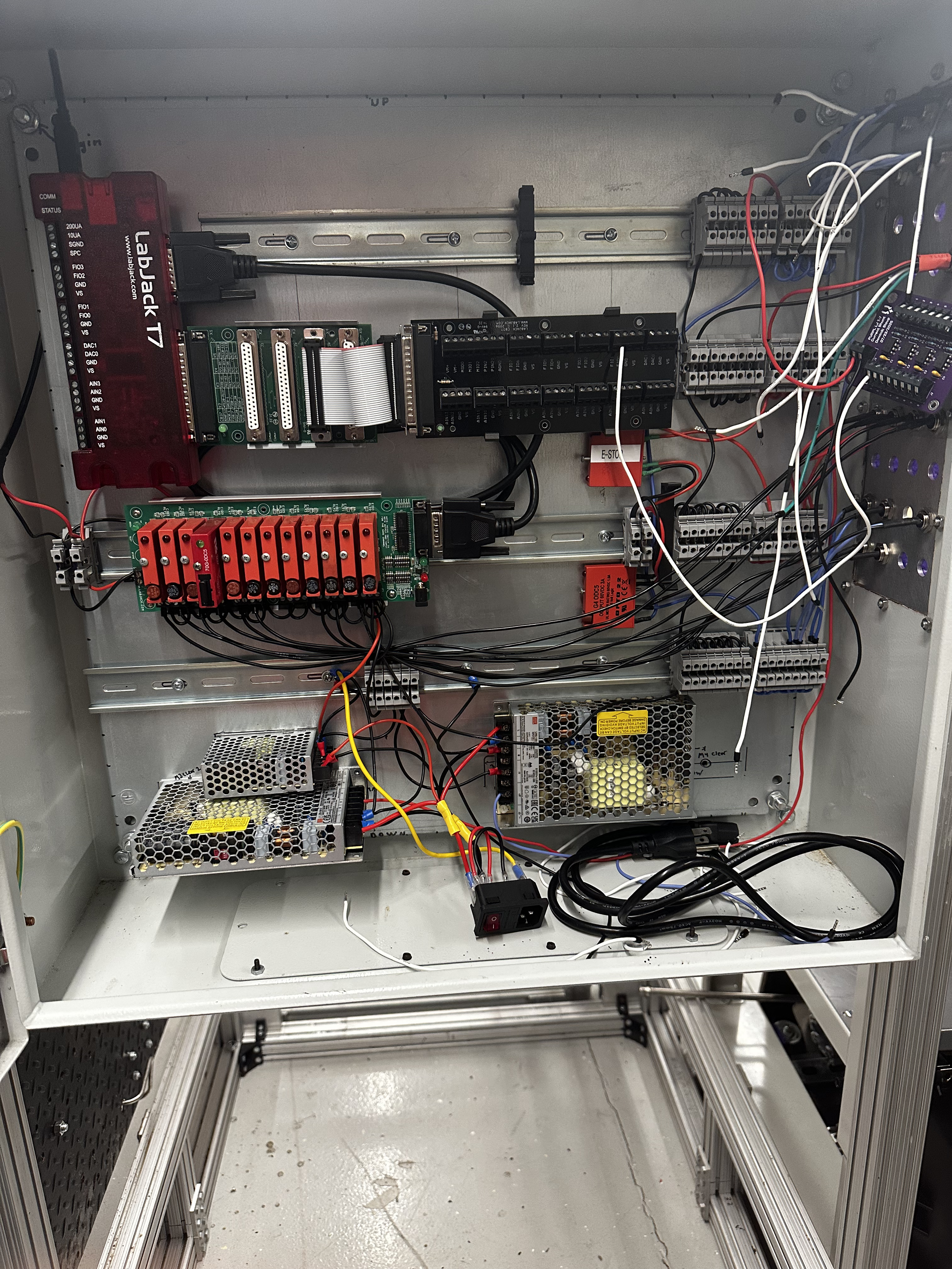

The DAQ (Ice Cube)

DAQ stands for data acquisition, but it isn’t necessarily just data acquisition. It’s really where the digital controller and accessories for all the instrumentation lives, from which the stand is operated. We currently use a LabJack T7 as our controller with a Python program to run the controls.

Pictured on the right was the DAQ about half way through the Fall 2025 semester. There has been lots of improvement since then, as we are now preparing for another test campaign towards the beginning of the Spring 2026 semester.

Our requirements increased drastically, and now it will support 20 solenoids, about 20-30 pressure transducers, 5-10 thermocouples, 3 load cells, and 2 e-regulators. The pictures from the Spring 2025 hot fire above show around 6 PTs, so you can imagine the increase of hardware.

So far, most of the work on the DAQ has been very technical rather than design, but I’ve recently taken up leadership over our electronics team and I hope to create more opportunities for myself and my teammates to do embedded hardware and more software design.

Current and Future Endeavors

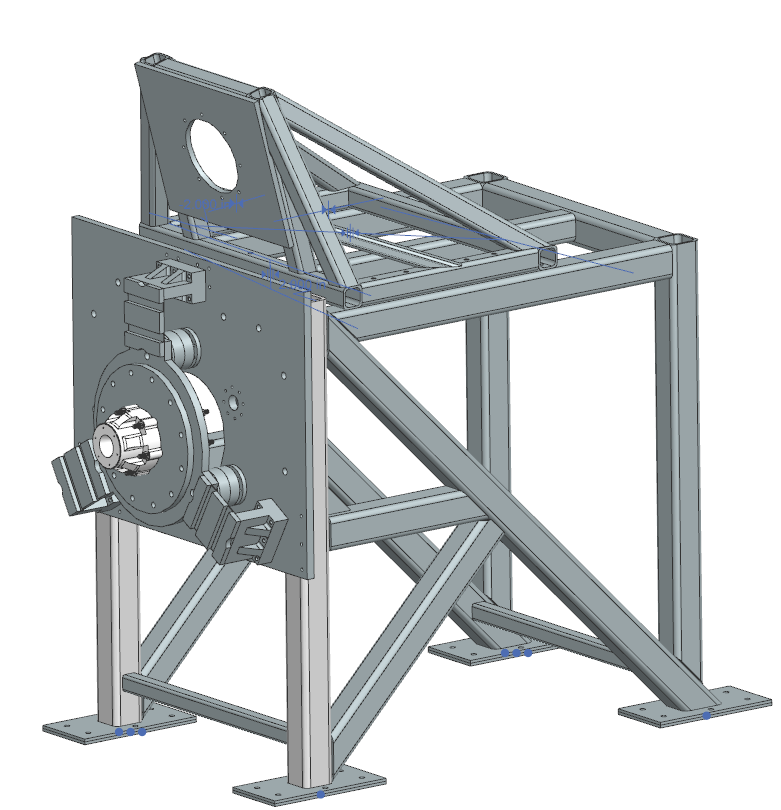

Currently, we are working on the improvements I mentioned for our upcoming test campaign. We plan to fire our test engine, Maelstrom, shown on the right. We will also do cold runs with our turbopump. Which leads to our future endeavors.

We are aiming to be the first collegiate propulsion team to fire a turbopump fed engine, and it is becoming a reality very quickly. On test infrastructure, we are switching gears from Biggie-K to our new test stand, Tachyon, which will support our turbopump team’s new engine theoretically capable of 5000lbf of thrust when using the turbopump.

I will be heading the new DAQ system for Tachyon, which will need to support even greater requirements than the increased requirements for Biggie-K. This upcoming semester will be a challenging but immensely rewarding period for our team.

I am mostly excited because we are switching to an NI system, and we will use LabView, which will enable us to have a much more powerful system than with our current LabJack

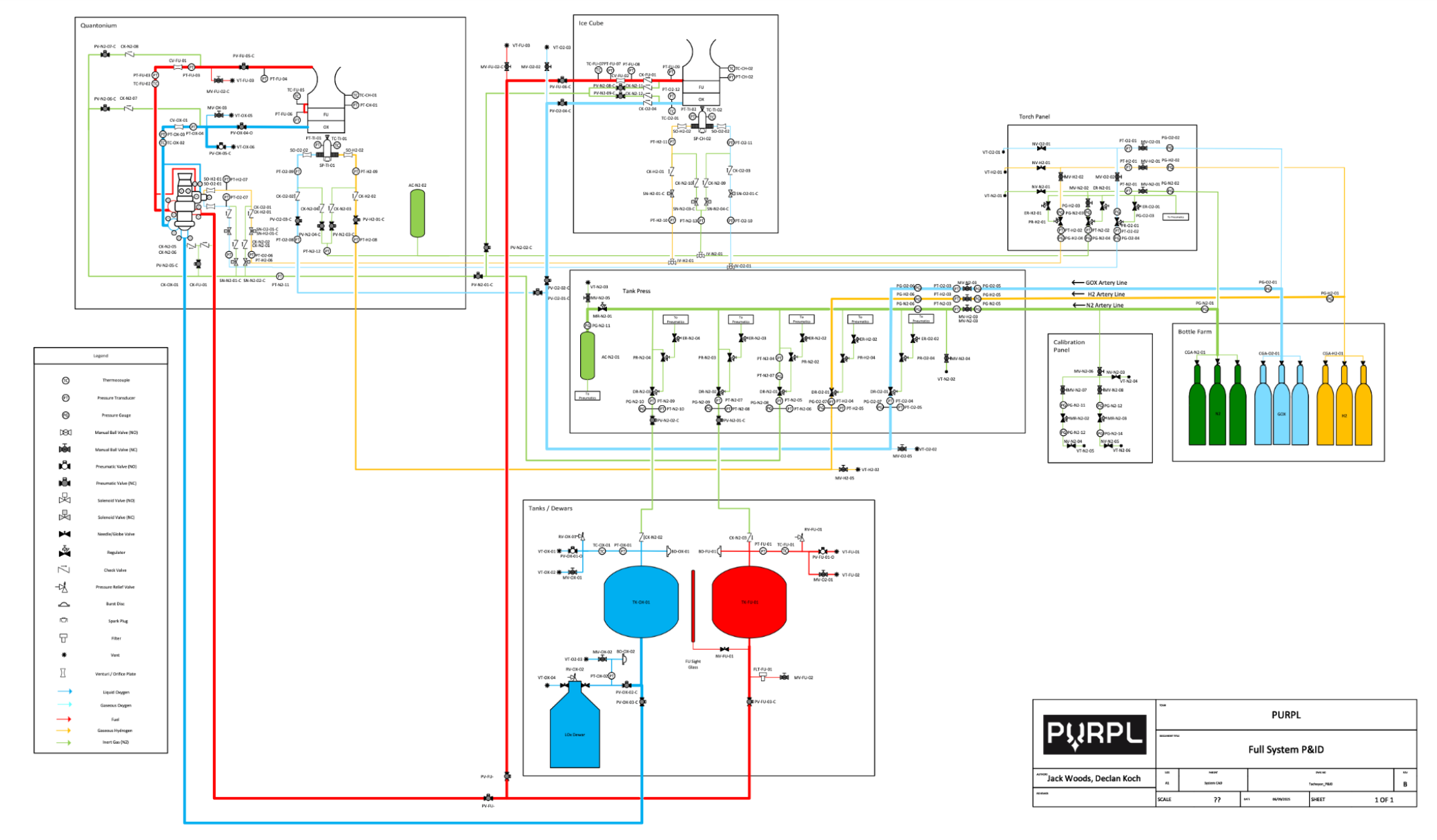

The piping and instrumentation diagram for Tachyon

Our test bed team’s engine, Maelstrom

Our thrust structure for Tachyon, Quant